Terei ea Acrylic ke mofuta oa mofuta oa terei e sebelisoang haholo maemong 'ohle a bophelo. Ponaletso ea eona e ikhethang, ho tšoarella, le ho iketsetsa lintho ka mokhoa o ikhethileng li etsa hore e ratoe 'marakeng. Tlhoko ea' maraka oa ho iketsetsa lintho ka terei ea acrylic e ntse e hola. Liindasteri le lits'ebetso tse fapaneng li na le litlhoko tsa tsona bakeng sa boholo, sebopeho, ts'ebetso le boleng ba literei. Literei tse tloaelehileng tse tloaelehileng li ke ke tsa fihlela litlhoko tsena ka botlalo, kahoo ho iketsetsa lintho ka terei ea acrylic ho ba bohlokoa le ho feta. Ka ho iketsetsa lintho ka terei ea acrylic, likhoebo li ka fumana litharollo tsa terei tse lumellanang le lihlahisoa tsa tsona, lits'ebetso tsa ts'ebetso, le setšoantšo sa lets'oao, ho ntlafatsa ts'ebetso ea thepa, ho fokotsa tahlehelo, le ho bontša setšoantšo sa profeshenale.

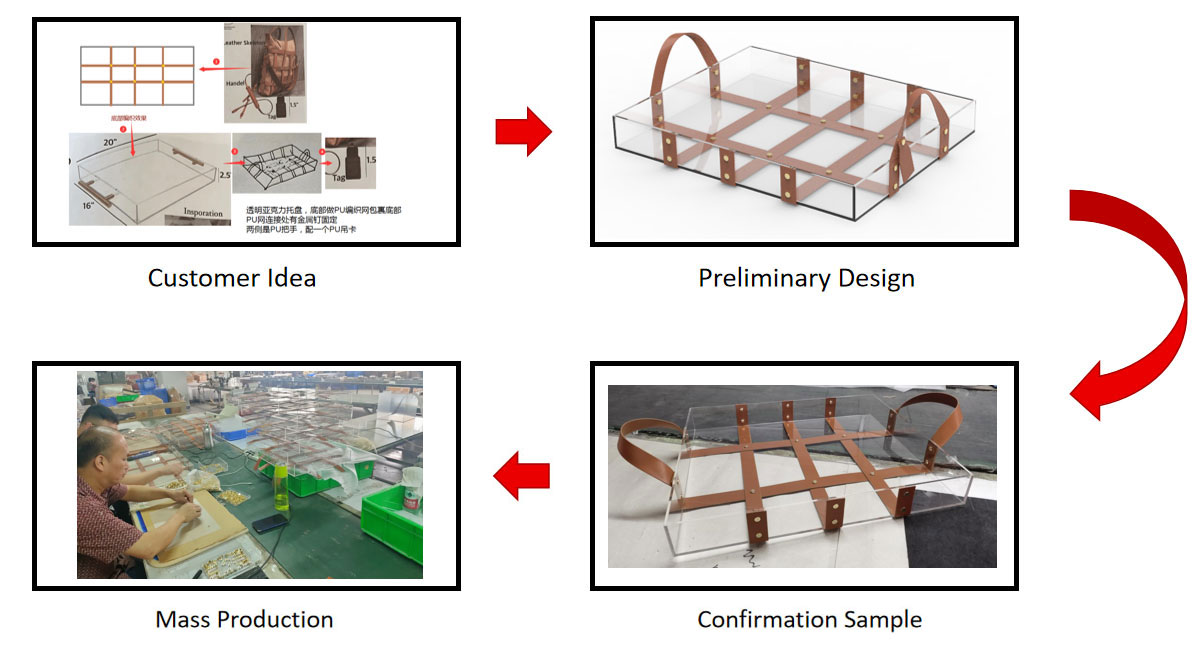

Sehlooho sa sengoloa sena ke ts'ebetso ea ho fetola terei ea acrylic. Re tla hlahisa mekhahlelo e fapaneng le lihokelo tsa ho fetola terei ea acrylic ka botlalo, ho kenyeletsoa tlhahlobo ea tlhoko le puisano, mohato oa moralo, khetho le ts'ebetso ea thepa, tlhahiso le kopano, jj. Ka ho shebisisa lits'ebetso tsena ka botebo, babali ba tla ithuta ho etsa literei tsa acrylic tsa boleng bo holimo ho latela litlhoko tsa motho ka mong.

Ka mor'a moo, re tla hlahloba ka botebo mokhoa oa ho fetola terei ea acrylic ho thusa babali ho utloisisa le ho sebelisa tsebo hamolemo tšimong ena ea profeshenale.

Mokhoa o Ikhethileng oa Terei ea Acrylic

A) Tlhahlobo ea Litlhoko le Puisano

Ts'ebetsong ea ho fetola terei ea acrylic, tlhahlobo ea tlhoko le puisano ke mehato ea bohlokoa haholo. E kenyelletsa puisano e sebetsang le kutloisiso pakeng tsa bareki le bahlahisi ba terei ea acrylic ho netefatsa kutloisiso e felletseng le kutloisiso e nepahetseng ea litlhoko tsa bareki.

Mokhoa oa puisano pakeng tsa moreki le moetsi:

Puisano ea Pele

Bareki ba qala ka ho ikopanya le moetsi ho hlalosa litlhoko le maikemisetso a bona bakeng sa ho fetola terei ea acrylic. Sena se ka etsoa ka mohala, imeile, kapa liboka tsa sefahleho le sefahleho.

Puisano ea Litlhoko

Moetsi o etsa puisano e qaqileng ea litlhoko le moreki ho utloisisa litlhoko tse ikhethileng tsa moreki, ho kenyeletsoa le litlhoko mabapi le boholo, sebopeho, ts'ebetso, bongata, nako ea ho tlisa thepa, jj.

Keletso ea Botekgeniki

Bahlahisi ba fana ka likeletso tsa botekgeniki tsa profeshenale ho latela litlhoko tsa bareki, ho kenyeletsoa le khetho ea thepa ea acrylic, ho khoneha ha moralo, le likarolo tse ling tsa tlhahiso.

Khoteshene le Konteraka

Moetsi o fana ka khotheishene e qaqileng e ipapisitseng le litlhoko tsa moreki le liphetho tsa puisano mme o fihlela tumellano ea konteraka le moreki.

Mokhahlelong oa tlhahlobo ea tlhoko le puisano, bahlahisi ba acrylic ba hloka ho mamela ka mafolofolo litlhoko tsa bareki, ho fana ka litlhahiso tsa litsebi, le ho boloka puisano le maikutlo a bona ka nako. Kutloisiso e felletseng le kutloisiso e nepahetseng ea litlhoko tsa bareki li tla rala motheo o tiileng bakeng sa mekhahlelo e latelang ea moralo le tlhahiso, ho netefatsa hore terei ea ho qetela ea acrylic e etselitsoeng uena e ka fihlela litebello le litlhoko tsa bareki ka botlalo.

B) Mokhahlelo oa Moralo

Mokhahlelo oa moralo ke mohato oa bohlokoa ts'ebetsong ea ho fetola terei ea acrylic, e kenyeletsang ho theha moralo o ikhethileng oa terei ea acrylic ho latela litlhoko tsa bareki le litlhoko tsa botekgeniki. Tse latelang ke mehato le lits'ebetso tsa bohlokoa mohatong oa moralo:

1. Moralo oa Pele:

- Ho ya ka ditlhoko le ditlhaloso tsa botekgeniki tse fanweng ke moreki, moetsi wa terei o etsa moralo wa pele. Sena se kenyeletsa ho fumana boholo, sebopeho, ponahalo, le dikarolo tse ding tsa motheo tsa terei ya acrylic, le ho taka ditshwantsho tsa pele tsa moralo.

- Nahana ka tikoloho ea ts'ebeliso le litlhoko tsa terei, joalo ka bokhoni ba ho jara mojaro, mokhoa oa ho bokella, mokhoa oa ho sebetsana le lintho, jj., ho netefatsa ts'ebetsong le ho sebetsa ha moralo.

2. Ho Etsa Mehlala le ho Bonahatsa ka 3D:

- Ka ho sebelisa software ea moralo e thusoang ke khomphutha, ho etsoa mohlala oa 3D, 'me moralo oa pele o fetoloa mohlala o itseng oa 3D. Kahoo nka bontša ponahalo le sebopeho se betere sa terei, 'me ka thusa bareki ho utloisisa ponahalo ea sehlahisoa sa ho qetela hamolemo.

- Bahlahisi ba ka sebelisa mehlala ea 3D bakeng sa tlhahiso e bonahalang e le hore bareki ba ka hlahloba moralo le ho fana ka litlhahiso tsa liphetoho. Sena se thusa ho netefatsa hore moralo o lumellana le litebello le litlhoko tsa moreki.

3. Nahana ka Boholo, Sebopeho le Mosebetsi:

- Mokhahlelong oa moralo, moetsi o hloka ho nahana ka boholo, sebopeho le mosebetsi oa terei. Boholo bo lokela ho fihlela litlhoko tsa bareki le litlhoko tsa ts'ebeliso e sebetsang, sebopeho se lokela ho ba se loketseng sehlahisoa 'me se be bonolo ho se sebetsana le ho se paka, 'me mosebetsi o lokela ho fihlela morero oa ts'ebeliso le litlhoko tse khethehileng tsa terei.

- Lintlha tse kang ho sebetsana le mathōko, sebopeho se jarang mojaro, le moralo o thibelang ho thella ha literei le tsona li lokela ho nahanoa ho netefatsa botsitso, ho tšoarella le polokeho ea literei.

4. Ntlafatsa le ho Netefatsa Khafetsa:

- Ho ya ka maikutlo le maikutlo a moreki, bahlahisi ba etsa diphetoho le ditokiso tse hlokahalang, ho fihlela moralo wa ho qetela wa moralo ho fumana kananelo le kgotsofalo ya bareki.

- Sena se ka hloka puisano le diphetoho tse ngata ho netefatsa hore moralo o tsamaellana hantle le ditebello tsa moreki le hore dintlha tsa kgonego le ditjeo tsa tlhahiso ya sebele di elwa hloko ka botlalo.

Bohlokoa ba mokgahlelo wa moralo wa terei ya acrylic bo ke ke ba hlokomolohuwa. Ka ho nahana ka boholo, sebopeho le tshebetso mmoho, bahlahisi ba kgona ho rala terei ya acrylic e ikgethileng e fihlelang ditlhoko tsa bareki. Diterei tse entsweng ka hloko di ka ntlafatsa bokgoni ba thepa, tsa fokotsa tahlehelo, le ho ntlafatsa setshwantsho sa letshwao. Ka hona, ho hlokahala ho ela hloko dintlha tse karolong ya moralo ho netefatsa hore morero wa moralo o a utlwahala le ho kgoneha ho fihlella phello e ntle ka ho fetisisa ya ho iketsetsa.

C) Khetho le Ts'ebetso ea Lisebelisoa

Khetho le ts'ebetso ea thepa ke karolo ea bohlokoa ea ts'ebetso ea ho fetola terei ea acrylic, e kenyeletsang khetho ea thepa e loketseng ea acrylic le ts'ebetso le tlhahiso e tsamaellanang. Mona ke tlhaiso-leseling e nepahetseng:

1. Litšobotsi le Litlhokomelo tsa Khetho ea Lisebelisoa tsa Acrylic:

- Ponaletso: Acrylic e na le ponaletso e ntle haholo, e leng se etsang hore e be thepa e loketseng bakeng sa ho bonts'a le ho bonts'a lihlahisoa.

- Ho tšoarella: Acrylic e na le khanyetso e phahameng khahlanong le tšusumetso le ho tsofala, 'me e ka mamella khatello le tšebeliso e kholo libakeng tsa thepa le tsa polokelo.

- Boima bo bobebe: Ha bo bapisoa le khalase, thepa ea acrylic e bobebe ebile e bonolo ho e sebetsana le ho e sebelisa.

-

E ka fetoloa: Acrylic e ka sebetsoa ka mokhoa o feto-fetohang le ho etsoa hore e lumellane le litlhoko tsa libopeho le boholo bo fapaneng ka mekhoa e kang thermoforming, ho seha, ho phunya, jj.

- Ha e kene lerōleng ebile ha e fetohe: Literei tsa acrylic li ka ba le litšobotsi tse thibelang lerōle le ho thibela ho fetoha ha lerōle ho sireletsa sehlahisoa lerōleng le motlakaseng o sa fetoheng.

Ha o khetha thepa ea acrylic, lintlha tse latelang li lokela ho nahanoa:

- Tikoloho ea ts'ebeliso le litlhoko tsa terei, ho kenyeletsoa mocheso, mongobo, ho kopana le lik'hemik'hale, jj.

- Litlhoko tsa ho jara mojaro le ho tšoarella ha diterei.

- Tekanyetso ea bareki le lithibelo tsa litšenyehelo.

2. Ts'ebetso le Theknoloji ea Ts'ebetso ea Terei ea Acrylic:

- Ho seha le ho bopa: Ho ya ka ditshwantsho tsa moralo, lakane ya acrylic e sehwa ka sebopeho le boholo bo lakatsehang ho sebediswa mochini wa ho seha kapa theknoloji ya ho seha ka laser.

- Ho etsa Thermoforming: Ka ho futhumatsa le ho bopa, lakane ya acrylic e sehilweng e bopjwa ka sebopeho se ikgethang sa terei. Sena se ka etswa ka sethunya sa mocheso, poleiti e chesang, kapa disebediswa tse etsang vacuum.

- Ho sebetsana le masoba le dikobo: Ho sebediswa mochini wa ho tjheka kapa theknoloji ya ho seha ka laser, masoba le dikobo di sebetswa poleiting ya acrylic ho nolofatsa ho bokella diterei, ho di lokisa, kapa merero e meng e itseng.

-

Kalafo ea bokaholimo: Ho ea ka litlhoko, terei ea acrylic e bentšitsoe, e saloa, kapa e phekoloe ka tsela e 'ngoe ea bokaholimo ho ntlafatsa boleng ba ponahalo le ho ama.

Ts'ebetso ea ts'ebetso e hloka ho tsamaisoa ke litsebi tse nang le boiphihlelo ho netefatsa boleng ba ts'ebetso le ho nepahala ha terei ea acrylic. Ka nako e ts'oanang, mehato ea polokeho e lokela ho eloa hloko nakong ea ts'ebetso ho netefatsa polokeho ea basebetsi le ts'ebetso e tloaelehileng ea lisebelisoa.

Ka khetho e nepahetseng ea thepa le mekhoa e nepahetseng ea ts'ebetso, bahlahisi ba ka hlahisa literei tsa acrylic tse etselitsoeng uena ka boleng bo holimo tse fihlelang litlhoko tsa bareki. Ka ts'ebetso e ntle le botšepehi bo botle, literei tsena li fana ka tharollo e sebetsang bakeng sa lits'ebetso tsa thepa le tsa polokelo.

Rea u amohela fekthering ea rona ea literei tsa acrylic tse ikhethileng! Re fana ka lits'ebeletso tsa ho iketsetsa tse etellang pele indastering, kahoo ebang u hloka ho iketsetsa lintho tsa hau kapa u batla ho iketsetsa sehlahisoa se ikhethang bakeng sa ketsahalo ea khoebo, re ka fihlela litlhoko tsa hau. Ho tloha moralo ho isa tlhahisong, sehlopha sa rona sa litsebi se tla ikitlaelletsa ho u etsetsa literei tsa acrylic tse ikhethileng, e le hore u ka ikutloa u le boiphihlelo bo ikhethang ts'ebelisong e 'ngoe le e 'ngoe.

D) Tlhahiso le Kopano

Ts'ebetso ea tlhahiso le lintlha tsa tekheniki tsa literei tsa acrylic ke senotlolo sa ho netefatsa boleng ba sehlahisoa sa ho qetela. Mona ke tlhaiso-leseling e nepahetseng:

1. Ts'ebetso ea Tlhahiso le Lintlha tsa Tekheniki:

- Lokisetsa thepa: Lokisetsa maqephe a acrylic a hlokahalang le likarolo tse ling ho latela boholo le litlhoko tsa sebopeho tse khethiloeng ke moralo.

- Ho seha le ho bopa: Ho sebelisoa mochini o sehang kapa theknoloji ea ho seha ka laser, lakane ea acrylic e sehoa ho latela litlhoko tsa moralo, 'me mokhoa oa thermoforming o sebelisoa ho e bopa hore e be sebopeho sa terei.

- Masoba le dikobo tsa mochini: Ka ho sebedisa mochini wa ho tjheka kapa theknoloji ya ho seha ka laser, masoba le dikobo di sebetswa ka hara lakane ya acrylic bakeng sa ho bokella diterei, ho di lokisa, kapa merero e meng e itseng.

- Kalafo ea bokaholimo: Ho polisha, ho sanda kapa kalafo e 'ngoe ea bokaholimo ba poleiti ea acrylic ho ntlafatsa boleng ba ponahalo le ho ama.

- Kopano: Ho ya ka ditlhoko tsa moralo, poleiti ya acrylic le dikarolo tse ding di kopantswe, tse kang dikhutlo tsa kgokelo, dikurufu tsa ho lokisa, jj., ho netefatsa botsitso ba sebopeho le botsitso ba tshebetso ba terei.

2. Taolo ea Boleng le Tlhahlobo ea Kopano:

-

Ts'ebetsong ea tlhahiso, taolo ea boleng e bohlokoa. Bahlahisi ba lokela ho theha maemo a thata a taolo ea boleng le ho etsa litlhahlobo le liteko ho netefatsa boleng le ho nepahala ha khokahano e 'ngoe le e 'ngoe ea tlhahiso.

- Mokhahlelong oa ho seha le ho bopa, hoa hlokahala ho netefatsa hore boholo, sebopeho le Sekhutlo sa lakane ea acrylic li fihlela litlhoko tsa moralo ho qoba ho kheloha ha boholo kapa ho fetoha ho hobe.

- Ha o sebetsa ka ho lokisa masoba le dikobo, hlahloba hore na boemo le boholo ba tsona di nepahetse, mme o netefatse hore masoba le dikobo di boreleli ebile di tsitsitse.

-

Mokhahlelong oa kalafo ea bokaholimo, ho etsoa ho bentša le ho hlohlora ka ho lekaneng ho netefatsa hore bokaholimo ba terei bo boreleli ebile ha bo na ho ngoapa, 'me lerōle kapa litšila lia tlosoa.

-

Mokhoeng oa ho kopanya, ho lekana le botsitso ba khokahano ea karolo ka 'ngoe li lokela ho hlahlojoa ka hloko ho netefatsa hore sebopeho sa terei se tiile ebile sea sebetsa.

Ka taolo e tiileng ea boleng le tlhahlobo ea kopano, bahlahisi ba ka netefatsa hore ha ho na mathata kapa likoli tsa boleng tse hlahang nakong ea tlhahiso ea literei tsa acrylic. Sena se thusa ho fana ka lihlahisoa tsa literei tsa boleng bo holimo le tse tšepahalang tse fihlelang litlhoko tsa bareki le ho netefatsa botšepehi le ho tšoarella libakeng tsa thepa le tsa polokelo.

Nyeoe ea Tray ea Acrylic e Ikhethileng

Kakaretso

Pampiri ena e bua ka mokhoa oa ho etsa le ho kopanya literei tsa acrylic, e hatisa bohlokoa ba taolo ea boleng le tlhahlobo ea kopano nakong ea ts'ebetso ea tlhahiso. Ka taolo e tiileng ea boleng le tlhahlobo ea kopano, bahlahisi ba ka netefatsa hore ha ho na mathata kapa liphoso tsa boleng tse hlahang nakong ea tlhahiso ea literei tsa acrylic, kahoo ba fana ka lihlahisoa tsa literei tsa boleng bo holimo le tse tšepahalang.

Mokhoa oa ho Itlhophisa ka Terei ea Acrylic o na le Melemo e Latelang:

- Ho iketsetsa: Literei tsa acrylic li ka etsoa hore li lumellane le litlhoko le litlhoko tsa bareki, ho kenyeletsoa boholo, sebopeho, ts'ebetso le ponahalo. Sena se nolofalletsa diterei tsa acrylic ho fihlela litlhoko tse ikhethileng tsa liindasteri le lits'ebetso tse fapaneng, ho fana ka litharollo tse ikhethileng.

- E bobebe ebile e tšoarella: Thepa ea acrylic e na le boima bo tlase, e leng se etsang hore literei tsa acrylic li be bobebe haholo, 'me li be bonolo ho li sebetsana le ho li sebelisa. Ka nako e ts'oanang, thepa ea acrylic le eona e na le botsitso bo botle 'me e ka mamella meroalo e boima le ho hanyetsa tšusumetso, e leng se netefatsang tšebeliso ea nako e telele ea literei libakeng tsa thepa le polokelo.

- Ponaletso le phello ea ponts'o: Terei ea acrylic e na le ponaletso e ntle, e ka bonts'a lihlahisoa ka ho hlaka, ea ntlafatsa phello ea ponts'o le ho hohela ha lihlahisoa. Sena se bohlokoa haholo bakeng sa barekisi le indasteri ea ponts'o ho hohela tlhokomelo ea bareki ka katleho.

- Tshebetso e thibelang ho sisinyeha le ho se sirele lerōle: thepa ea acrylic e ka phekoloa ka anti-static ho qoba tšenyo ea lihlahisoa le likarolo tsa elektroniki tse bakoang ke tšitiso ea motlakase. Ho phaella moo, bokaholimo bo boreleli ba terei ea acrylic bo boetse bo fokotsa ho bokellana ha lerōle le litšila, ho boloka bohloeki ba sehlahisoa.

Mokhoa oa ho Etsa Lintho ka Terei ea Acrylic o na le Menyetla e Meholo ea 'Maraka:

- Indasteri ea thepa le polokelo: Literei tsa acrylic li sebelisoa haholo indastering ea thepa le polokelo, e leng se ka ntlafatsang katleho ea lipalangoang le tsamaiso ea polokelo ea thepa. Ka kholo ea tlhoko ea thepa lefatšeng ka bophara, tlhoko ea 'maraka ea literei tsa acrylic e tla tsoela pele ho eketseha.

- Indasteri ea mabenkele le lipontšo: Literei tsa acrylic li ka fana ka phello e hlakileng ea pontšo ea lihlahisoa, e leng se etsang hore li sebelisoe haholo indastering ea mabenkele le lipontšo. Ka tlholisano e ntseng e eketseha ea mabenkele le khatiso ea bareki ponahalong ea sehlahisoa, tlhoko ea 'maraka ea literei tsa acrylic e tla tsoela pele ho hola.

- Indasteri ea lisebelisoa tsa elektroniki le tsa semiconductor: Matla a khahlanong le ho se fetohe ha literei tsa acrylic a li etsa khetho e ntle indastering ea lisebelisoa tsa elektroniki le tsa semiconductor. Ka nts'etsopele e tsoelang pele ea lihlahisoa tsa elektroniki le keketseho ea tlhoko, litei tsa acrylic 'marakeng oa indasteri li pharaletse haholo.

Ha re akaretsa, ts'ebetso ea ho fetola terei ea acrylic e na le melemo e mengata 'me e na le menyetla e mengata ea' maraka indastering ea thepa, polokelo ea thepa, mabenkele, lipontšo, lisebelisoa tsa elektroniki le liindasteri tsa semiconductor. Bahlahisi ba ka fihlela litlhoko tsa bareki ka lits'ebetso tsa tlhahiso ea litsebi le taolo ea boleng, 'me ba fana ka lihlahisoa tsa terei ea acrylic tsa boleng bo holimo, tse ikhethileng.

Nako ea poso: Phato-29-2023